Digital vs. Gravure Printing for Custom Pouches: Which is Right for Your Brand?

Selecting the right printing method for your custom pouches is more than just a production choice—it impacts cost, flexibility, and shelf appeal. While both digital and gravure printing produce high-quality results, they serve different business needs. Here’s a breakdown to help you decide which method aligns with your brand’s stage, budget, and packaging goals.

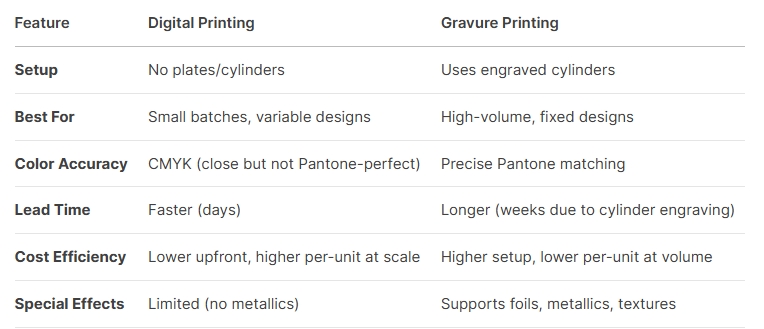

1. Key Differences Between Digital and Gravure Printing

2. When to Choose Digital Printing

Ideal for:

Startups testing designs

Limited-edition or seasonal runs

Brands needing quick turnarounds

Small-batch eCommerce/DTC products

Top Benefits:

✔ No minimum order quantities (MOQ) – Order as few as 100 pouches.

✔ Design flexibility – Easily update artwork between runs.

✔ Faster production – No plate setup means quicker delivery.Limitations:

Slight color variance (not ideal for strict brand guidelines).

Less durable for high-heat applications (e.g., retort pouches).

3. When Gravure Printing Shines

Ideal for:

Established brands with locked-in designs

Mass retail distribution

Products requiring exact Pantone matching

Heat-resistant packaging (e.g., pet food, supplements)

Top Benefits:

✔ Superior color consistency – Perfect for brand-critical hues.

✔ Cost-effective at scale – Lower per-unit price for large orders.

✔ Advanced finishes – Metallic inks, gloss/matte effects.⚠ Limitations:

Higher upfront costs (cylinder engraving).

Less adaptable to design changes.

4. Hybrid Approach: Start Digital, Scale with Gravure

Many brands begin with digital printing to:

Test market response

Refine designs before finalizing

Minimize upfront costs

Once a product gains traction, they transition to gravure for:

Bulk cost savings

Retail-ready color precision

Enhanced durability

This strategy balances agility and scalability without wasted inventory.

5. Sustainability & Material Considerations

Digital

Lower waste (no plate changes between runs).

Compatible with recyclable films.

Gravure

Longer-lasting prints reduce repackaging needs.

Better for high-barrier, mono-material pouches.

Which Method is Right for You?

Ask these questions:

Is my design finalized? → Gravure for precision, digital for flexibility.

What’s my order volume? → Digital (<10K units), Gravure (>10K units).

Do I need special finishes? → Gravure for foils/metallics.

How quickly do I need pouches? → Digital for speed.